PCB (printed circuit board) is called “the mother of electronic system products.”

In life, what products need PCB circuit boards?

Not every electrical appliance needs a circuit board. Simple electrical appliances may not need a circuit, such as a motor. However, electrical appliances with specific functions generally require circuit boards, such as televisions, smartphones, and computers.

PCB board generally refers to the rigid printed circuit board, Mainly used in computer motherboards, mouse boards, graphics cards, office equipment, printers, copiers, remote controls, various chargers, calculators, digital cameras, TV motherboards, limited TV signal amplifiers, mobile phones, washing machines, electronics Scales, telephones, LED lamps, etc.; and used in home appliances: air conditioners, refrigerators, stereos, MP3; used in industrial equipment: GPS, automobiles, instrumentation, medical equipment, aircraft, military weapons, missiles, Satellite, etc.

Recently, the iphone12 series of smartphones were officially released, supporting 5G, equipped with an A14 Bionic chip, 12 million pixels wide-angle dual-lens rear camera system. A new antenna system is used to improve 5G performance. Let us take a look at which circuit board types are used in a smartphone.

FPC – Flexible Printed Circuit can be bent into any shape of the circuit board.

With the rapid expansion of applications such as smartphones, tablets, LED TVs, and ultra-thin laptops, leading consumer electronics products to the trend of miniaturization, refinement, and portability, global consumer electronics products have entered an era of thin and light diversification. FPC: Many smartphones and smart hardware applications have brought more and more market space for FPC.

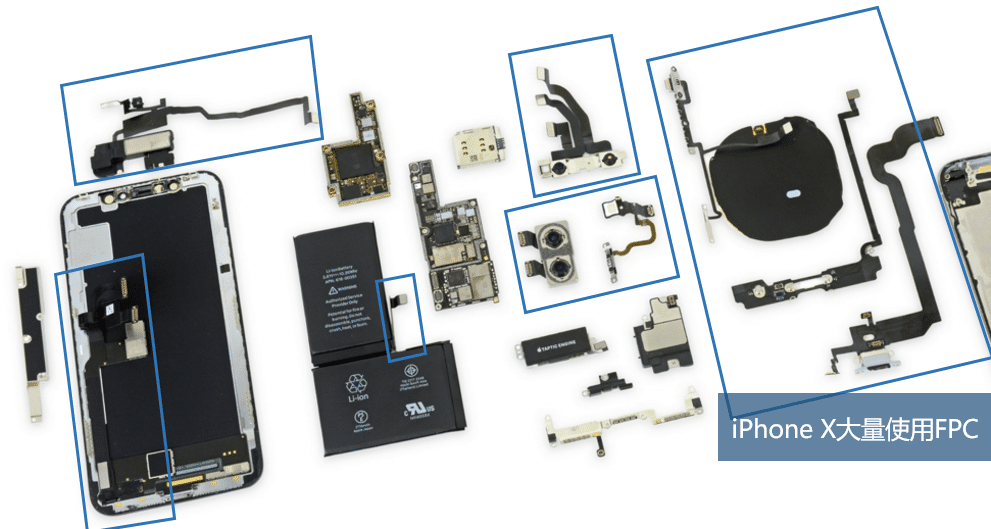

FPC flexible circuit boards can be used in smartphones, such as cameras, display screens, touch screens, batteries, antennas, fingerprint modules, and buttons. With the advent of 5G networks, the amount of FPC flexible circuit boards has continued to increase, mainly reflected in the application of multiple cameras, under-screen fingerprint modules, radio frequency antennas, folding screens, flexible screens, and malleable functions. The amount of FPC flexible circuit boards in a single smartphone can be increased to about 20 pairs. FPC flexible circuit boards occupy a large advantage in folding screen mobile phones, which can achieve hundreds of bends, which can meet the development needs of folding screen mobile phones; the size is light and thin, conducive to reducing the thickness of the folding screen mobile phone.

According to the type of base film, FPC can be divided into PI, PET, PEN, etc. Flexible Copper Clad Laminate (FCCL) and a flexible insulating layer bonded together with adhesive. PI cover film FPC is the most common type of flexible circuit board, further subdivided into single-sided FPC, double-sided FPC, multilayer FPC, and rigid-flex PCB board.

| Types | Features |

| Single-sided FPC | Lightweight, thin thickness, suitable for consumer electronics |

| Double-sided FPC | In the same volume, the signal transmission capacity is greater than single-layer FPC. Double-sided FPC is the main FPC type in smartphones. |

| Multilayer FPC | Press multiple single-layer FPCs together, and drill the multi-layer circuit to conduct. It has the advantage of a single-layer FPC, which doubles the number of high-precision circuits loaded per unit area through stacking. |

| Rigid-flexible FPC | Rigid-flex PCB is the combination of Flexible PCB and rigid PCB. Flex PCB can be bent. Rigid PCB can bear weight. Compared with ordinary PCB, rigid-flex PCB of the performance and stability are higher, and the available space is optimized. Mainly used in smartphones for display panels, batteries, and camera modules. |

Apple is a firm supporter of FPC. Its iPhone uses up to 16 FPCs and is the world’s largest FPC purchaser. As the most important growth driver of FPC, smartphones benefit from Apple and its demonstration effect. FPC has penetrated rapidly and has maintained a high growth rate every year since 2009. In 2017, it was the only bright spot in the PCB industry and became the only category that achieved positive growth.

The FPC flexible circuit board manufacturing industry appeared in the 1960s. Countries with advanced electronic technology, such as the United States, first applied FPC to the application fields of sophisticated electronic products such as aerospace and military. After the end of the Cold War, FPC began to be used in civilian products. At the beginning of the 21st century, the booming consumer electronics industry pushed the FPC industry into a period of rapid development. However, due to the continuous increase in production costs in European and American countries, FPC production’s focus has gradually shifted to Asia. As the main undertaking country of the FPC industry, China has benefited from the new industrial transfer wave. At present, FPC’s total output value in China is in a leading position in the world.

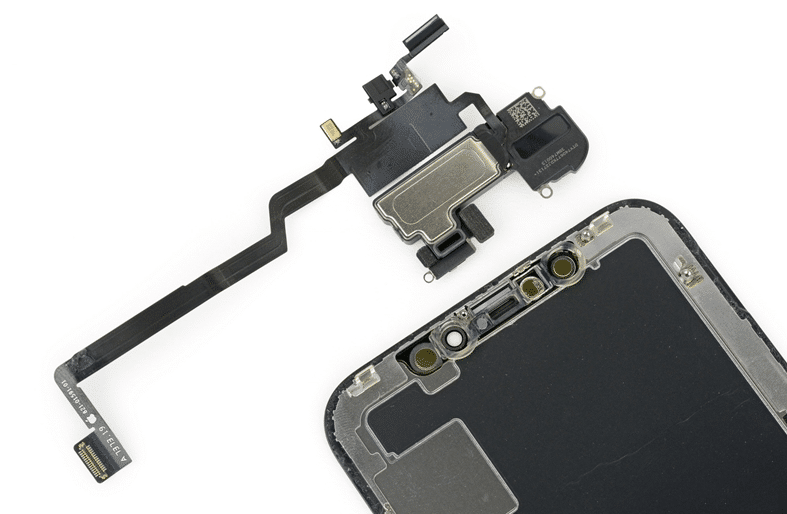

As shown below, in iPhone X, FPC is widely used. LCD, original deep sense camera, dual camera, side buttons, USB port, and battery are connected to the motherboard using FPC. (The same is true for other mobile phones, every inch of land is expensive).

In wearable devices, smart hardware, and small IoT devices, FPCs are also widely used.

Features of FPC

FPC is made of flexible substrates such as polyimide or polyester film. It has the advantages of high wiring density, lightweight, thin thickness, and high flexibility. It can withstand millions of dynamic bending without damaging the wires. The space layout requirements can move and expand arbitrarily, realize three-dimensional assembly, and achieve component assembly and wire connection integration. It has advantages that other types of circuit boards cannot match.

- Flexible

It can be bent and can withstand thousands of bends without breaking because the inner copper foil and the outer film are both soft.

- Thin

The thickness of the common FPC is only 0.15mm, and the line width is 0.1mm. The general wire should be at least 0.5mm thick, and the space for 2 wires is enough for 10 FPC circuits.

- Any shape

FPC is like cutting paper. It can be cut into any shape and fit on smart hardware products’ inner surface, taking up almost no space.

| Characteristic | Description |

| Small size and lightweight | Compared with Rigid PCB, the flexible PCB board is about 90% lighter under the same current carrying capacity and saves about 60%-90% of space. |

| Assembly and connection consistency | Easy to install and connect, no wrong connection occurs when installing the connecting line, and the probability of electronic failure is low. |

| Controllability of electrical parameter design | Can control capacitance, inductance, characteristic impedance, delay, and attenuation, etc. |

| Low-cost | 1. Port connection, easy to replace; 2. Simplified structural design, reducing wire clamps and their fixing clamps |

| Bendable | Able to achieve three-dimensional assembly |

| Fast heat dissipation | Can effectively improve heat dissipation performance |

FPC internal circuit distribution

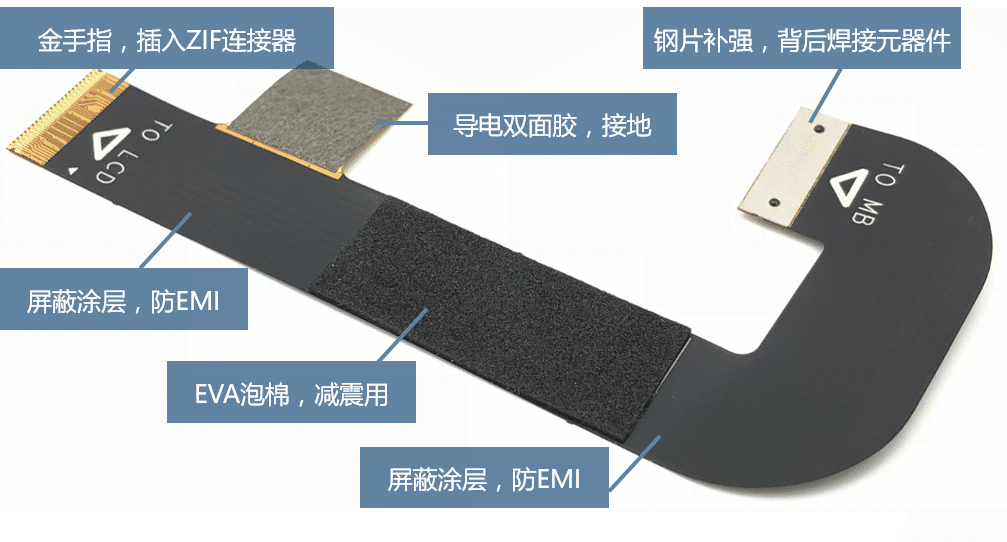

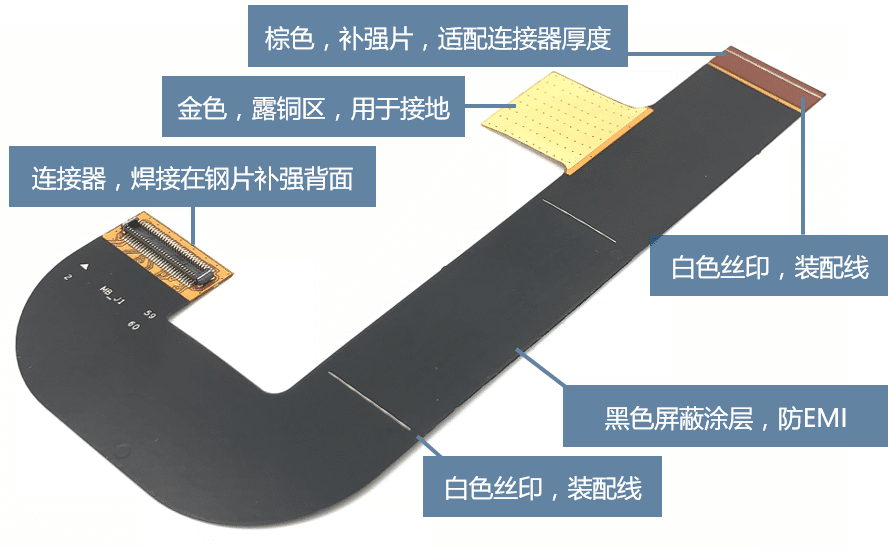

The main ones used in smartphones and smart hardware products are complex FPCs, as shown in the figure below.

Regarding the internal circuit of the FPC, it can be understood as a double-sided PCB board. Both are implemented by adding vias to two layers of circuits.

In addition to the circuit, there are many other components in the picture.

A detailed explanation of each component of FPC

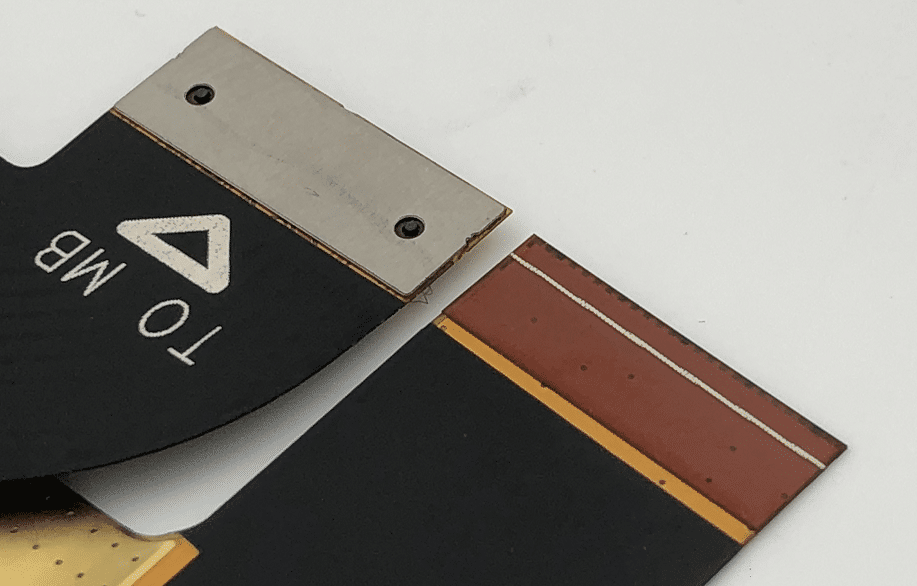

- Stiffener: supplement the strength of FPC

FPC can be bent because it is thin. The thinness also has its drawbacks. For example, if the components are soldered on the FPC, they will be forced off if they are too soft. Therefore, there are stainless steel or resin reinforcing ribs in the component area of the FPC so that the component area cannot be bent to protect the components.

FPC connectors can’t be as thin as 0.15mm, usually 0.2-0.3mm, so they also need to be reinforced.

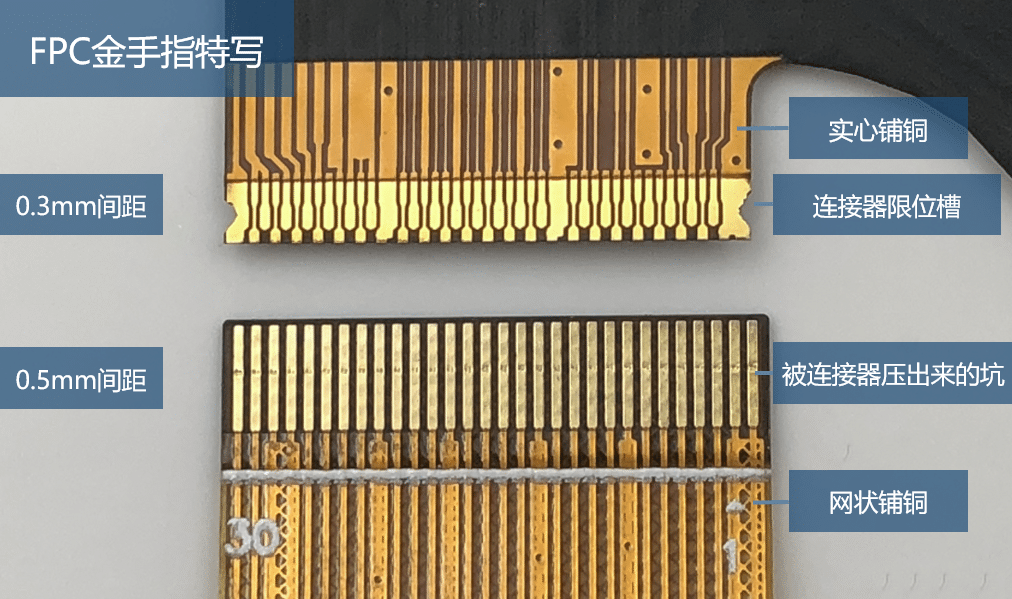

Thicken the FPC golden finger part to fit the ZIF connector.

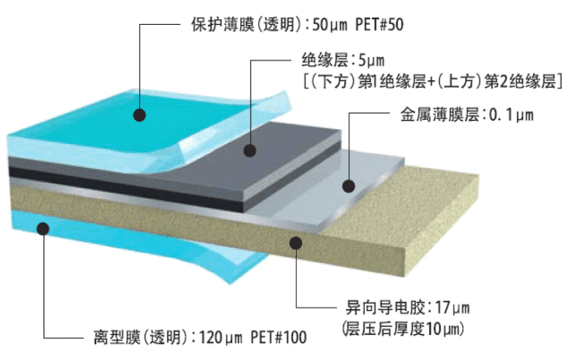

- Shielding coating (electromagnetic shielding film)

The black layer is the black insulating paint on the circuit board and a metal film inside. The metal film and the ground of the FPC are connected to achieve the shielding effect.

For high-speed signal lines such as LCD screens and cameras, a shielding layer should be used on the FPC to avoid external signal radiation and EMI electromagnetic interference.

The iPhone’s FPC uses full shielding, while many small cottage products have no shielding layer, directly exposing the yellow FPC substrate.

- others

The silkscreen line is used to judge whether it is installed in place during production and assembly. Improve production efficiency and production quality.

The conductive tape is used to connect the ground wire of the FPC to the ground of the motherboard or chassis. Enhance anti-static ability and anti-radiation ability.

EVA foam, the FPC in the picture above, is a smart speaker FPC. EVA foam can prevent resonance noise between the FPC and the chassis.

High-Density Interconnect Technology PCB (HDI PCB)

Compared with traditional PCBs, HDI PCBs are smaller, lighter, more reliable, and more robust-HDI PCBs are an ideal solution for wearable, mobile, and handheld electronic products.

Ball Grid Array PCB(BGA PCB)

The most important part of the smartphone is the “CPU.” This circuit board includes various sensors and corresponding support circuits.

The smartphone’s main circuit board is equipped with SMD components, which are arranged very closely, and the main chips on the circuit board are soldered on the circuit board in the form of BGA.

BGA’s full name is Ball Grid Array (PCB with ball grid array structure), a packaging method for integrated circuits using organic carrier boards. Its characteristics are small package area, powerful function, and increased number of pins; PCB board can be self-centered during welding and easy to tin; high reliability; good electrical performance, and low overall cost.

Concluding remarks

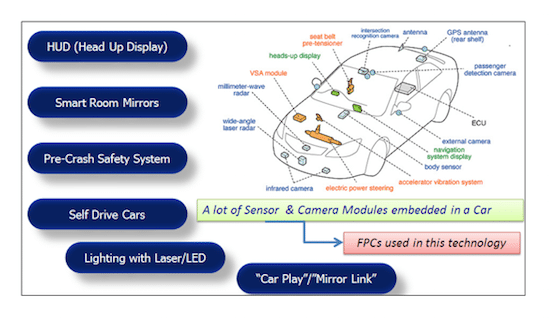

In addition to being widely used in electronic products such as smartphones, FPC flexible circuit boards are also well-deserved in automotive electronics. As can be seen from the chart below, especially the introduction of automotive infotainment and ADAS, the number of FPCs used in the automotive market has increased sharply, which is expected to surpass smartphones’ market size.

Related Posts:

- How To Buy Prototype PCB Boards?

- Five factors that FPC PCB designers should know about impedance control

- Knowledge of Plating on Flexible Circuit Board Surface

- Knowledge of Flexible Printed Circuit Board Processing Technology

- The terms you have to know related to the manufacture of Flexible PCB

- Best PCB Manufacturer In China