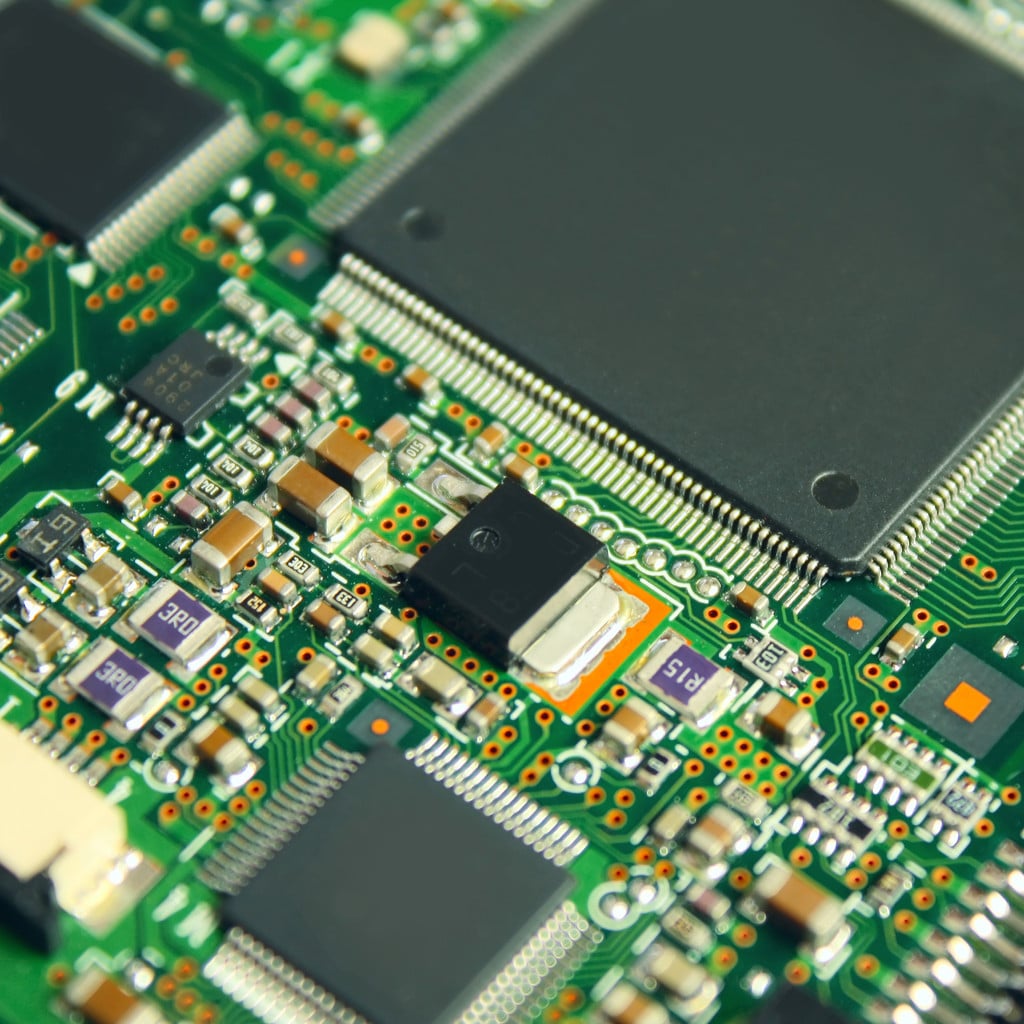

When it comes to building a printed circuit board, there are some things you need to understand. One of them is surface mount technology (SMT). As simple as this may sound, it can determine whether or not you will build a PCB that will stand the test of time. This is due to the role it plays in the mounting of electrical components directly on a PCB’s surface.

Introduction to Surface Mount Technology

Surface mount technology places short lead or leadless components (SMC or SMD) on the corresponding pads on the circuit board during electronic assembly. And then, solder components to circuit boards using reflow, wave, or hand soldering.

The application of SMT assembly technology has the advantages of miniaturization, high performance, high reliability, and high efficiency.

Talking about surface mount technology, it has some important elements or materials that you must know. The good part is that you have come to the right place where all these will be explained. This article will be listing out materials that are used in SMT assembly.

Materials Used in Surface Mount Technology

This is similar to powered solder. The only difference is that it is been suspended by flux paste. One of the reasons why solder paste has become very popular is that it contains lead-free alloys. Also, it plays the role of an adhesive in attaching SMDs/SMCs onto the surface of a printed circuit board.

Some of the most common elements of solder paste are tin, silver, and copper. Their respective ratios are 96.5%, 3.0% and 0.5%. Bi14/Sn43/Pb43 has long been known to always perform very well in solder paste with its low melting temperature.

Flux

Flux is another important material in SMT assembly that is worth talking about. Many people have the misconception that it is also the same as solder paste mentioned above. This is not true as it is only a part of solder paste. In other words, solder paste contains some flux. The role it plays is helping to ensure the soldering is smooth.

It can assist in the removal of dirt from the surface of a metal. That is to say, it helps in getting oxides dissolved. This will ensure the molten metal becomes wet. Furthermore, the presence of flux can help in prevention of oxidation.

Adhesive

It may surprise you to know that adhesive is an integral part of SMT assembly. These can help in ensuring that components are fixed properly to printed circuit boards during double-sided reflow or wave soldering. With the aid of an adhesive, it becomes possible for SMD to be mounted to PCB. This will ensure components are not displaced during processes that are characterized by high speed.

Cleaning Agent

Once solder paste has been successfully applied, there will be residue or remains on the board. These have to be cleaned off using a cleaning agent. Also, it helps in ensuring SMT adhesives are removed from printing pencils. An alcohol-based cleaning agent will have the most impact.

Once surface mount soldering has been completed successfully, cleaning agent will be used on printed circuit board. This helps to guarantee electrical functions, extended life, and reliability of appliances.

Final Words

Having seen the above, it is very obvious that there are some crucial materials that must be used in SMT assembly. Anything short of these can mean disaster for your printed circuit board.