Whether you assemble a printed circuit board yourself or a circuit board assembled at a PCB assembly plant, it needs to be cleaned after assembly.

PCBAs need to be cleaned because the boards are more or less inevitably contaminated during the assembly process.

In this article, you will learn why and how to clean PCBAs.

Why clean PCBA?

During PCB assembly, operator fingerprints, factory dust, flux and activator residues, oxides, etc., can all contaminate the PCB surface.

These pollutants make the PCBA unsightly, but most importantly, it will affect the quality of the PCBA.

PCB assemblers who pursue high quality will clean the PCBA after it is assembled, which is a necessary part.

Here are some reasons why PCBAs are cleaned before packing and shipping.

- Military/medical PCBs that require extreme precision need to be cleaned

Military and medical PCBs require high precision and reliability. In extreme environments (high temperature and humidity), contaminants or dust on the surface of the PCB or components may absorb moisture, destroy the solder mask, and eventually cause a short circuit on the circuit board.

Conversely, clean PCB surfaces and components are more reliable and last longer. Plus, it also looks more pleasing.

- Be sure to clean the PCB before applying the conformal paint

Conformal paint is applied to PCB components as a protective coating to prolong their life. According to statistics, after cleaning the PCBA, the brushing strength of the conformal paint will increase by 50% and be more uniform.

If you do not clean the surface of the PCB and apply the conformal paint, it may cause cracks on the surface of the PCB.

- There are contaminants on the surface of the PCB after soldering

No matter how tidy the environment of the PCB assembly plant is and how advanced the assembly technology is, the surface of every PCB assembly will be contaminated. This is because there will be operator fingerprints or flux residues on the board’s surface during assembly.

For the above reasons, we clean all PCBAs before packing and shipping.

What is the safest way to clean a PCB assembly?

To not damage the components on the assembled circuit board, we need to choose the most suitable cleaning agent and cleaning method. Below we will introduce 3 methods of cleaning PCBA in detail.

1. Semi-automatic online cleaning of PCBA

Semi-automatic in-line cleaners can be used to clean PCBs and small batches of PCBAs.

The advantage of the semi-automatic online cleaning machine is that it is safe and fast, but it has requirements for cleaning solvents and is not suitable for large quantities of PCBs and PCBAs.

Semi-automatic online cleaning machines can be used in any link of the production line. When using a semi-automatic cleaning machine to clean the PCBA, a clamp is required to fix the PCBA.

2. Fully automatic online PCBA cleaning machine

A fully automatic in-line cleaning machine is a safe and fast cleaning method for PCB and PCBA cleaning and is suitable for cleaning many PCB assemblies.

The fully automatic online PCBA cleaning machine can complete the processes of water-based chemical cleaning, water-based rinsing, and drying.

A fully automatic online PCBA cleaner requires solvents that are compatible with components, PCB surface finish, PCB solder mask, etc.

A fully automatic online PCBA cleaning machine can be used to clean aerospace, military, and medical PCBs.

The disadvantage of the fully automatic online PCBA cleaning machine is that its cleaning equipment is relatively expensive and requires cleaning solvents.

The automatic cleaning process is divided into water cleaning, semi-water cleaning, and solvent cleaning.

The tools and materials for automatic cleaning mainly include a water cleaning machine, deionized water system, conductivity tester, beaker, deionized water.

Automated cleaning PCBA steps

Step 1. Preparation of deionized water: use electrodialysis device and ion exchange resin tank to prepare deionized water;

Step 2. Conductivity test: Use a conductivity tester to test water conductivity after electrodialysis and ion exchange resin tanks, respectively; if all meet the index requirements, it can be used for water cleaning.

Step 3. Introducing the water cleaning machine: Introduce the deionized water in the water storage tank to the water cleaning machine.

Step 4. Set the parameters of the washing machine: the temperature of the washing room and the rinsing room is set to 60±10℃; the temperature of the drying room is set to 60-90℃.

Step 5. Set the chain speed: generally control the chain speed at 50-150cm/min.

Step 6. After the PCBA is cleaned, take it out of the cleaning machine and store it in an anti-static turnover container. The anti-static turnover container must be clean and dust-free to avoid secondary pollution of the cleaned PCBA.

3. Manual cleaning of PCBA

Manual cleaning of PCBAs is suitable for small batches of PCBAs that require MPC cleaning solvent.

Manual cleaning of PCBA uses a chemical water-based cleaning method done in a constant temperature bath.

Manual cleaning of PCBA is also suitable for cleaning PCB and PCBA, but there are requirements for the temperature of the water.

PCBA manual cleaning method has lower cost and higher cost performance.

Tools for manual cleaning of PCBA include cleaning cans, spray cans, brushes, IPA or VIGON EFM, gloves, deionized water, wipes (dust-free paper), air guns, airtight bags, etc.

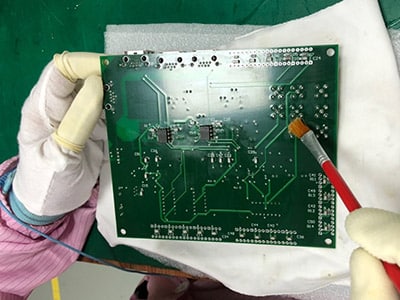

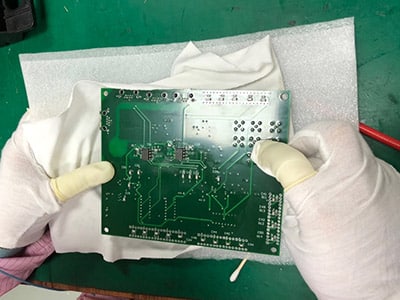

Manual cleaning of PCBA steps

Step 1. Clean the PCBA in IPA or VIGON EFM, or spray the IPA and EFM on the surface of the circuit board, using about 10 ml per 4 square inches.

Step 2. Use a moist, soft short-bristle brush to wipe the circuit board continuously for about 10 seconds;

Step 3. Rinse with deionized water, about 10 ml per 4 square inches, which can effectively remove potential contaminants (dust and residual flux, etc.);

Step 4. Hold the edge of the circuit board and wipe off the excess deionized water with a clean lint-free cloth (dust-free paper).

Step 5. Visually inspect the cleanliness of the circuit board;

Step 6. If necessary, use an air gun to dry the circuit board;

Step 7. If you need to store the circuit boards or components for some time before applying the conformal paint, please put the circuit boards or components in a sealed bag containing desiccant.

Although the manual cleaning method of PCBA can effectively reduce costs, its efficiency is low, and the cleaning is not comprehensive. For example, the manual cleaning method cannot completely clean the gaps of many electronic components, and integrated circuits such as ICs have many dense pins, which are closely attached to the PCB, and the brush cannot enter into it for cleaning.

Therefore, the manual cleaning method is gradually replaced by automatic cleaning.

JHYPCB is a professional PCB manufacturing and assembly supplier you can trust. We can provide you with high-quality and highly reliable PCB prototype manufacturing services; we can also provide you with prototype PCB assembly, partial turnkey PCB assembly, and Full turnkey PCB manufacturing services.

Related Reading

- How To Clean The Solder Paste On SMT Stencil

- What is the difference between wave soldering and reflow soldering?

- SMT PCB Assembly Manufacturing Process Introduces

- Materials Used in Surface Mount Technology

- Testing & Inspection Methods For PCB And PCBA

- X-Ray Inspection In PCB Assembly

- How to Solder On Flex PCB?

- Complete Introduction To Flexible PCB Assembly Process