All materials have their shelf life, but some have a longer shelf life, and some have a shorter shelf life. What’s wrong with using expired materials? Think about what will happen if you eat out-of-expiration food? What’s wrong with using out-of-expiration PCB?

Before answering the question “use of expired PCB,” I’d like to ask you, what is the purpose of PCB? What does it need to be processed in the electronic assembly factory?

The most significant function of PCB is to transmit electronic signals as the carrier of electronic parts, so if there are parts that cannot be welded to the PCB or contact points that can not effectively transmit electronic signals, it will affect the function of electronic products, or cause intermittent dysfunction.

So how are electronic parts welded to PCB?

The current PCB welding process almost uses a high temperature of about 240 ~ 250 °C to melt the solder (solder paste or tin wire) to connect the electronic parts solder pins and PCB. Hence, the question comes, whether the expired PCB can withstand at least two times high temperatures above 250 °C without problems, the reason for bearing two times high temperatures is because the general PCBA process is now a double-sided welding plate.

Based on the above understanding, it’s time to take a look at “what might happen if we use out-of-expiration PCB?” The following problems do not necessarily occur, but they all involve risks, so if you still want to use expired PCB, you must make sure that the following issues do not happen:

An expired PCB board may cause oxidation of the PCB surface pad.

The oxidation of the solder pad will result in poor soldering, which may eventually lead to a functional failure or parts loss risk. Different surface treatments of the circuit board will have other effects on antioxidation. In principle, ENIG PCB Board requires it to be used up within 12 months, while OSP PCB Board requires it to be used up within six months. I suggest you follow the shelf life of the PCB board factory(PCB Manufacturer) to ensure quality.

OSP PCB can generally be sent back to the PCB factory, wash off the OSP film, and then put on a new layer of OSP. Still, there is a chance to damage the copper foil circuit when OSP pickling is removed, so you’d better consult the PCB factory to confirm whether the OSP film can be reprocessed.

ENIG PCB board cannot be reprocessed. It is generally recommended to “press bake” and then test whether there is a problem with solderability.

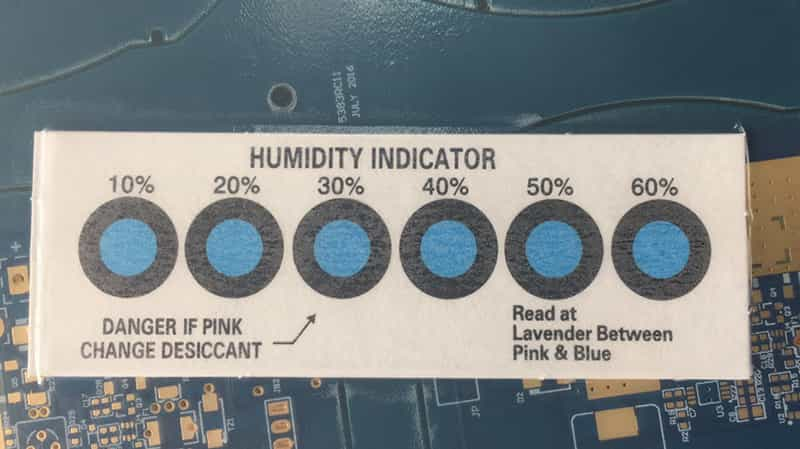

THE Out-of-expiration PCB board may cause a burst due to moisture absorption.

When the printed circuit board is resoldered after moisture absorption, it may cause problems such as the popcorn effect, plate explosion, or delamination. Although this problem can be solved by baking, not every kind of printed circuit board is suitable for baking, and baking may cause other quality problems.

Generally speaking, the OSP PCB board is not recommended to bake because high-temperature baking will damage the OSP film, but I have also seen some people take OSP to bake. Still, the baking time should be shortened as much as possible, and the temperature should not be too high. After baking, it is more necessary to go through the back soldering furnace in the shortest time, which is a great challenge; otherwise, the welding pad will be oxidized and affect welding.

The gluing ability of expired PCB may degrade and deteriorate.

After the circuit board is produced, the bonding ability between layer to layer will gradually degrade or even deteriorate with time. That is to say, with the increase of time, the bonding force between layer to layer of the circuit board will gradually decrease.

When such a circuit board passes through the high temperature of the rewelding furnace because the circuit board composed of different materials will have a different coefficient of thermal expansion, under the action of thermal expansion and cold shrinkage, it is possible to cause circuit board de-lamination and surface bubbles, which will seriously affect the reliability and long-term reliability of the circuit board, because the circuit board delamination may break the conduction via, between the circuit board layer and layer, resulting in low electrical characteristics. The most troublesome thing is that there may be intermittent problems, which are more likely to cause CAF (micro-short circuit) that we don’t know.

Related Posts:

- Custom Circuit Board Printing

- Best PCB Manufacturer In China

- How to Choose the Right PCB Manufacturer and Supplier

- How To Buy Prototype PCB Boards?

- What factors determine the price of PCB?

- Find Out Now, What Should You Do For Fast PCB Classification?

- How to Store PCB and PCBA?

- How long can PCBA finished products be stored?