You know that one particular smell you get when your electric appliance or wires have burned away due to a short circuit, right? This causes a state of panic and a warning of some severe expenses. The same can happen in the case of PCBs too. Just like wires burn out, PCBs can short circuit too. So, the next time you get that weird yet particular smell from your electronic device, you may guess that it is a short-circuited PCB. But, don’t just jump to the decision. Make sure you know that it is that particular fault and not something else. So, how do you make a check? You can follow four critical steps to check for a short circuit in a PCB assembly from China. Here they are.

Step 1 – Visual inspection

The first and foremost step is that of visually inspecting your PCB. You can use a magnifying glass or a low magnification microscope. Look for tin whiskers between solder joints and pads or any kinds of cracks or blobs of solder. Check for all the vias; poorly plated vias can create a short circuit between layers. Burned spots on the PCB mean the fast is terrible! If you cannot see any such problems visually, you will need to go down further into the internal layers of the PCB. So, how do you do that? Through Infrared Imaging. Using an infrared camera, you can locate areas where a large amount of heat is being generated on the PCB.

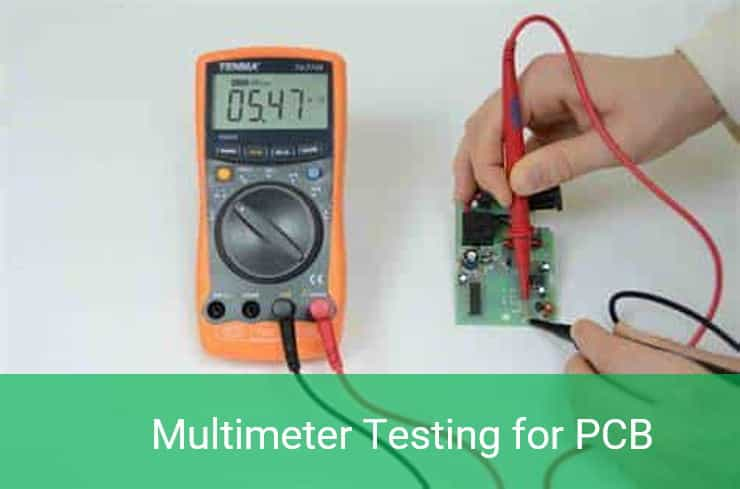

Step 2 – Multimeter testing

If your eyes are unable to do the job because the short may be a complicated or unnoticeable one, you will need to use a multimeter. This tool helps check the resistance between different points in the circuit. Track down the physical locations having problems using this tool. Short circuits may also involve a ground plane. Set one probe on a ground connection, and touch the other probe throughout other conductors on the board. The conductors that are not tied to the ground will read a very high resistance. If the multimeter reading is low, but you do not have an inductor between the conductor and ground, you may have harmful components. Using a multimeter, you must measure the resistance between pins on an IC or connector. Also, check that the resistance between pads/pins concerning each other and the ground connection is low.

Step 3 – Component checking

If none of the above works to help you, it may be faulty components or incorrect installation of your components. Check any suspect components. You may also check for any bulges in the PCB indicating that a particular part has gone wrong or burnt.

Step 4 – Destructive testing

With nothing in hand yet, the last retort is then destructive testing, which requires an X-ray imaging unit to examine the board’s interior without destroying it. However, if you don’t have access to an X-ray imaging unit, you can then remove your components and rerun your multimeter tests. This will help to easily access every point of the PCB, minus the elements. It will also help test whether the board itself is defective or if the pads on the board are faultily bridged internally.

All of the above is very time-consuming and grueling. To avoid all such laborious tasks, you must make sure that you bring in only tested PCBs into your premises before installing them into your products. Thus, you need a manufacturer who builds the best PCBs and tests them rigorously before delivering them to you. JHYPCB is one such manufacturer that uses only the best components to make PCBs and has every PCB assembly from China tested at the in-house test fixture before delivering the same to clients.

JHYPCB is a highly reliable PCB manufacturing and assembly service provider that has provided high-quality PCB manufacturing and assembly services to customers all over the world. All products comply with IPC standards, low cost and fast delivery are our tenets. Free inquiries are welcome.

Advanced Learning:

- PCB Design Guidelines

- 10 Tips To Improve PCB Design For Manufacturability

- What are the aspects of PCB Design For Manufacturing (DFM) and Design For Assembly (DFA)?

- Design For Manufacturability And Assemblability Of Printed Circuit Board

- What is the risk of using an out-of-expiration PCB?

- Testing & Inspection Methods For PCB And PCBA

- Flying Probe Testing For PCB

- X-Ray Inspection In PCB Assembly

- 30 Common SMT PCB Assembly Defects